Industrial Rope Access

At

Dangle, we specialise in

industrial rope access

training and

services, catering to sectors like wind, renewables, oil & gas, and construction. Our expert team ensures safety and efficiency, helping clients reduce maintenance costs while reaching new heights in operational excellence. Let’s reach the unreachable, together!

In this Comprehensive Guide to Industrial Rope Access: We look at What It Is, Benefits, and Applications

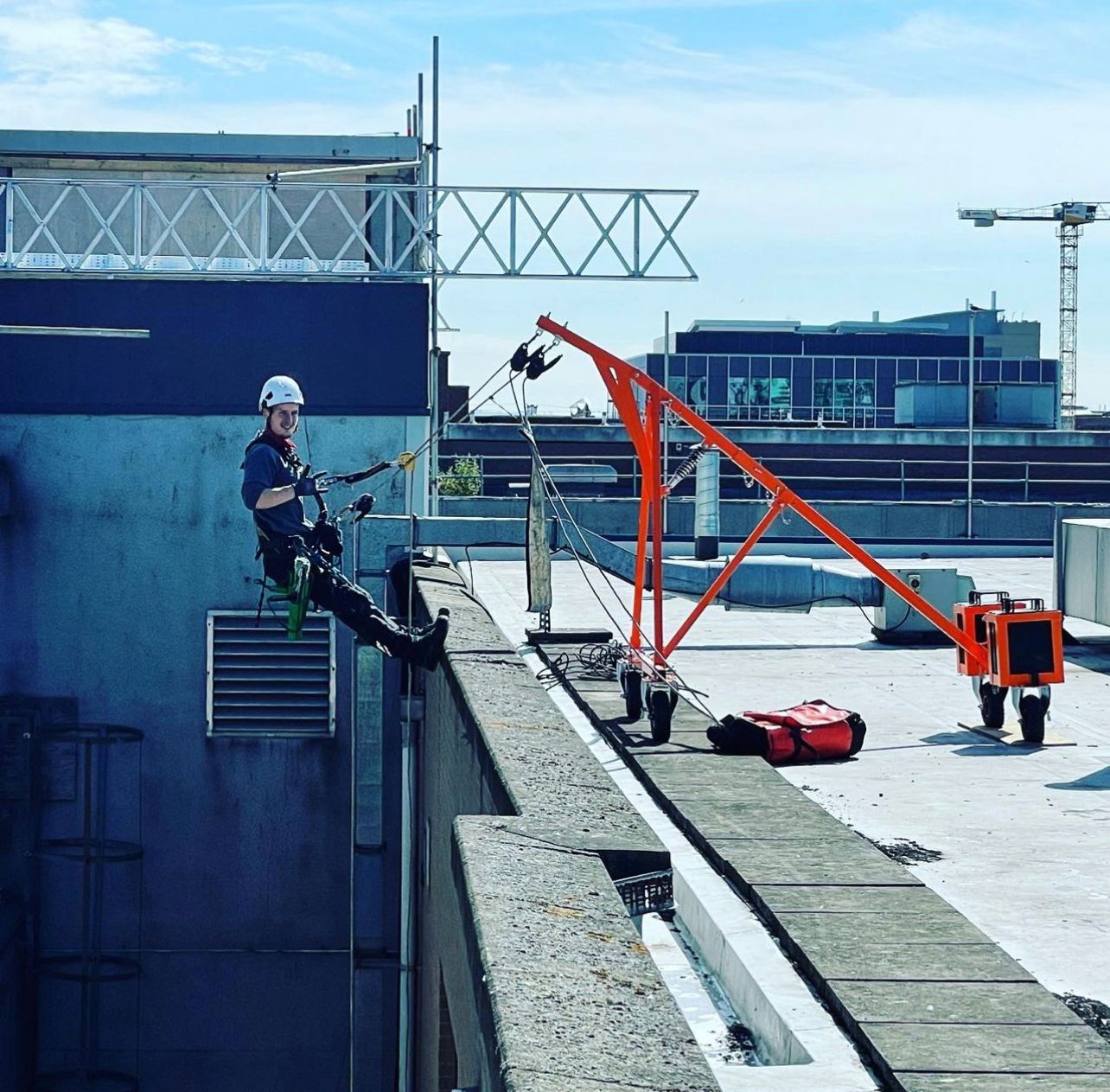

Industrial rope access is a specialised technique used by trained professionals to access difficult-to-reach areas in various industries. This method involves using ropes, harnesses, and other equipment to safely navigate and work at height. It is widely considered one of the most effective and efficient solutions for maintenance, inspection, and construction tasks in high-rise buildings, offshore platforms, and other challenging environments.

In this guide, we’ll explore what industrial rope access is, its benefits, common applications, safety standards, and why it is increasingly becoming the go-to solution for industries that require working at heights.

What Is Industrial Rope Access?

Industrial rope access (IRA) is a work-at-height technique where technicians use ropes, climbing harnesses, and other gear to access difficult or elevated areas. It was initially developed by the climbing and mountaineering community and has since been adapted for industrial use. Unlike traditional scaffolding or aerial work platforms, rope access allows for a more flexible and agile approach to reaching heights.

Rope access systems are primarily used for tasks such as inspections, cleaning, maintenance, and repairs. The technique is popular in industries like construction, energy, telecommunications, and offshore oil and gas. Technicians trained in industrial rope access use two independent rope systems to ensure safety: one rope supports their weight, while the second provides a backup in case of failure.

Benefits of Industrial Rope Access

There are numerous reasons why industrial rope access is becoming a preferred method for working at heights. Here are some of the key benefits that make it stand out:

1. Cost-Effectiveness

One of the primary advantages of industrial rope access is its cost-effectiveness. Traditional methods of accessing elevated work areas, such as scaffolding, cherry pickers, or cranes, can be expensive due to setup, equipment, and labor costs. With rope access, the need for heavy machinery is eliminated, reducing operational expenses. Additionally, the fast setup and teardown of rope access systems save both time and money.

2. Flexibility and Speed

Rope access provides unparalleled flexibility when it comes to working in hard-to-reach locations. Workers can quickly and easily access multiple areas without the need to reposition equipment or build scaffolding. This is especially beneficial for tasks like inspections or small-scale repairs, where the worksite is constantly changing.

3. Minimal Disruption

Since rope access technicians use minimal equipment, they cause less disruption to ongoing operations. For example, in a busy industrial plant, scaffolding might block pathways or limit access to critical areas. Rope access technicians, on the other hand, can work in tight spaces without interfering with other activities. This makes it ideal for environments where maintaining normal operations is crucial.

4. Safety Record

Safety is paramount when working at heights, and industrial rope access has safety at its core. Technicians are trained to adhere to strict safety standards, using multiple ropes and redundant systems to ensure they remain secure during their work. Additionally, the ropes and harnesses used in industrial rope access are tested to withstand heavy loads, and workers are equipped with personal protective equipment (PPE) such as helmets, gloves, and eye protection.

5. Access to Remote Locations

In some industries, technicians need to access hard-to-reach areas that are far from conventional access points. For example, offshore oil rigs or wind turbines often require workers to climb to high or isolated locations. Rope access allows technicians to reach these remote areas without the need for expensive cranes or helicopters, significantly reducing costs and logistical challenges.

Applications of Industrial Rope Access

Industrial rope access is used in a variety of industries, ranging from construction to energy. Below are some of the most common applications of this technique:

1. Building Maintenance and Facade Inspections

One of the most common applications for industrial rope access is building maintenance and facade inspections. High-rise buildings, such as skyscrapers and office towers, require regular inspection and maintenance of their facades. Traditional scaffolding can be time-consuming and disruptive, but rope access allows workers to access different levels of the building quickly and efficiently. Tasks such as window cleaning, painting, repairing structural elements, or inspecting the integrity of the building’s exterior can be easily carried out using industrial rope access.

2. Offshore Oil and Gas

In the offshore oil and gas industry, rope access is used for maintenance and inspection of platforms, rigs, and pipelines. The harsh environmental conditions and limited space on offshore platforms make rope access an ideal solution for accessing difficult-to-reach areas. Technicians can use rope access to carry out non-destructive testing, maintenance of equipment, cleaning, and inspection tasks without disrupting ongoing operations.

3. Telecommunications

Telecommunications companies often need to access high towers and masts to perform maintenance, repair, or installation of equipment. Rope access provides an efficient way to reach these towers without the need for large cranes or lifts. Technicians use rope access to install antennas, maintain satellite dishes, or inspect structural elements of telecom towers, ensuring minimal downtime for communication services.

4. Wind Turbine Maintenance

The wind energy sector is another industry where industrial rope access plays a vital role. Technicians are frequently required to inspect and maintain wind turbines, which can be located offshore or in remote locations. Using rope access, workers can access the blades, tower, and other critical components of wind turbines to conduct inspections, repairs, and replacements, ensuring that the turbines continue to operate at peak efficiency.

5. Industrial Cleaning

Rope access is commonly used for cleaning and maintenance tasks in large industrial facilities, such as factories, refineries, and power plants. Cleaning industrial equipment, boilers, and chimneys can be difficult due to the height and location of these components. Using industrial rope access, cleaning crews can reach these elevated areas quickly and safely, without the need for expensive scaffolding or cranes.

6. Surveying and Inspection

Industrial rope access is often employed in surveying and inspection tasks, where professionals need to assess the structural integrity of buildings, bridges, dams, and other infrastructure. These inspections may involve visual checks, ultrasonic testing, or the use of drones or cameras to capture images of the areas being inspected. Rope access allows workers to access difficult spots on structures where ladders or scaffolding might not be feasible.

Industrial Rope Access Safety Standards

Safety is the most critical aspect of industrial rope access work. The potential risks involved in working at height require workers to adhere to strict safety regulations and use the best equipment available. To ensure the safety of technicians, industry organisations such as the Industrial Rope Access Trade Association (IRATA) and the Society of Professional Rope Access Technicians (SPRAT) who both set standards for training, certification, and operational procedures across the globe.

1. Training and Certification

Before using rope access systems, technicians must undergo comprehensive training to obtain certification. The two most recognised certification bodies are IRATA and SPRAT. Both organisations offer tiered training programs that equip technicians with the skills needed to safely perform rope access work. These programs include both theoretical lessons and practical assessments, ensuring that workers are proficient in using ropes, knots, harnesses, and other equipment.

2. Equipment Standards

Rope access equipment must meet rigorous safety standards. The ropes, harnesses, and other gear used by technicians are designed to withstand high loads and are tested to ensure their reliability. Additionally, the ropes, harnesses and lifting equipment must be regularly inspected to check for wear and tear, ensuring that the equipment remains in top condition.

3. Safety Procedures

Technicians must follow strict safety procedures while working at height. This includes using two independent ropes for redundancy, maintaining clear communication with team members, and regularly checking equipment. In addition, technicians are required to have emergency procedures in place, including rescue plans, in case something goes wrong.

4. Rigorous Risk Assessment

Before each job, a thorough risk assessment must be conducted. This includes evaluating the site, identifying hazards, and developing strategies to mitigate potential risks. For example, the risk of falling debris, inclement weather, or other hazards must be considered, and safety measures should be implemented accordingly.

Industrial rope access has become a widely adopted solution for industries that require workers to perform tasks at height. The method’s cost-effectiveness, flexibility, and minimal disruption to ongoing operations make it an attractive choice for a wide range of applications. Whether it’s maintaining high-rise buildings, inspecting offshore oil rigs, or cleaning industrial facilities, rope access provides a safe, efficient, and reliable way to access hard-to-reach areas.

As the demand for rope access services continues to grow, the importance of safety standards and proper training cannot be overstated. Technicians must be highly skilled and certified to ensure that they can work safely and effectively in challenging environments. For companies in industries that require regular maintenance, inspections, or repairs at height, investing in industrial rope access can provide substantial benefits in terms of cost, efficiency, and safety.

If you’re considering industrial rope access for your business or project, make sure to work with a reputable service provider who follows industry best practices and safety guidelines. With the right team, industrial rope access can be a game-changer for your operations.

Why Choose Dangle's Academy

Here at Dangle, we pride ourselves on offering a wide range of professional and comprehensive inspection, access, coatings, and composite (IACC) industrial services and training courses to cater to the needs of both the private and public sectors. Our dedication to providing high-quality work at height solutions and training has helped us establish a strong reputation in the industry.

With a team of highly skilled and experienced professionals, we are committed to delivering exceptional results that not only meet but exceed our clients' expectations. Our on-site working at height services are designed to minimise maintenance costs in the long and short-term, allowing our clients to save on valuable resources.

Located in Belfast, Northern Ireland, our headquarters serve as the centre of our operations across Ireland. However, we also have a Dangle office based in Scotland, ensuring that we can extend our services to a wider clientele across the United Kingdom. No matter where you are located, our team is always ready to assist you with your industrial maintenance or training needs.

If you would like to learn more about how our dedicated team can help you, we encourage you to get in touch with us today. Our friendly and professional staff are always available to provide you with the information and support you require.

Contact us now to discover the Dangle difference and let us be your trusted partner in meeting your industrial service and training needs today.

We'd Love a Share...

You might also like